Materials

We offer you a clearer choice, and this page highlights our range of materials that are used, read on for more detail about them.

Whilst glass is the main feature in every structure we design and install, the additional elements required to fabricate the structure are equally important too - this section details more information on the various different types and finishes of glass as well as all the other components as well.

Glass Specification & Types

Whatever your glazing requirements, at Next Generation we can recommend the most suitable glass make up for your individual project. Which has been fabricated in the UK, by the leading glass processors to the highest British and European Standards.

There are thousands of different glass specification combinations available. Glass specification helps control the environment within the property and can assist in the minimalism of the structure’s impact, or even creatively enhance the surrounding architecture.

There are a number of considerations when specifying the glass for any project, which we will be able to advise you on and guide you through, taking all your needs and requirements into account.

Each different type of glass has its specific function. Please see some of the different glass types & functions listed below.

Annealed (Float) Glass

Manufactured by floating molten glass on a bath of liquid tin, the cooled slowly, to produce a perfectly flat surface on both sides, annealed glass forms the basis of the other more advanced glass types.

It is the weakest of the glass types and when it breaks it does so in large shards, therefore it is not considered a safety glass and is not suitable for overhead glazing.

Toughened (Tempered) Glass

Created by accelerating the cooling process of annealed glass, toughened or tempered glass is around five times stronger than annealed glass, making it the strongest of the glass types.

It is considered safe for overhead glazing (up to 5m above floor level) and is often the preferred choice for Roof Glazing. When toughened glass breaks it forms balls rather than shards, which minimise the potential for injury.

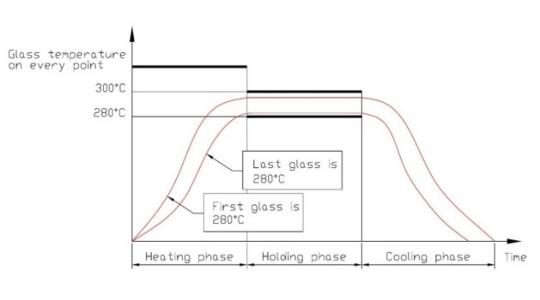

Heat Soak Tested Toughened Glass

Heat Soak Tested (HST) glass is created by heating to extremely high temperatures and then cooling quickly.

This process filters out approximately 95% of Nickel Sulphide Inclusion (NiS), which is an unavoidable matter found in about 1% of glass and could cause sudden breakage.

Next Generation offer HST glass as standard to assure premium quality glass with every rooflight.

Laminated Glass

Laminated glass is simply two or more layers of either annealed or toughened glass combined with interlayers.

Laminated glass is commonly used on the inner panes of rooflights as it offers increased security, safety, sound proofing, heat insulation, UV protection and durability.

When broken, the interlayer holds together, so the glass doesn’t fall in. Although not as strong as toughened glass, laminated glass is a popular choice due to it’s security and safety features.

Heat Strengthened Glass

Heat Strengthened (HS) glass is made by heating float glass in the furnace and then slowly cooling. It is approximately two times stronger than annealed glass and is less susceptible to breakage.

It also has a flatter surface so has less optical distortions. In it’s own right, it is not a safety glass and not suitable for overhead glazing. However, it is widely used with laminated glass for additional strength and can be a good solution for larger designs.

Insulated Glass Units

Insulated Glass Unit (IGU) is the generic term given to two or more panes of glass, sealed around the edges with a cavity space between them. IGUs are more commonly referred to as Single Glazed Units (SGU), Double Glazed Units (DGU) or Triple Glazed Units (TGU).

Glass Faces: ‘Face’ is the term used to numerically identify the glass surfaces in order from the exterior to the interior of the rooflight build up.

SGUs: Have 2 faces; face 1 – exterior side of the pane & face 2 – interior side of the pane.

DGUs: Have 4 faces; face 1 – exterior side of the outer pane & face 2 – interior side of the outer pane, next to the cavity, face 3 – top side of the inner pane, next to the cavity & face 4 – the under side of the interior pane.

TGUs: Follow the same pattern as above but have 6 faces.

Glass Finishes & Extras

Finishes vary and can often be utilised in multiple combinations.

You may wish for the glass to be obscured for added privacy or environmental impact or coated for improved performance and maintenance advantages.

Here are just some of the Glass Extras available to you:

- Solar Control – for increased thermal performance. Ideal for south facing properties

- Low Maintenance – is a very fine, virtually invisible Teflon like coating, intended to extend the time between cleans and prevent water staining

- Low Iron Glass – made from carefully selected silica with very low iron content, giving ultra clear glass

- Patterned Glass – usually used for privacy or obscurity where light transmission is still important

- Anti-Slip Glass – highly recommended on units that are intended to be walked on, to create a ‘rough’ surface for increased slip resistance

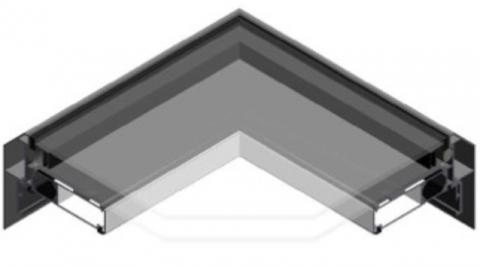

Other elements

While glass is the main feature in every structure we design and install, the additional elements required to fabricate the structure are equally important.

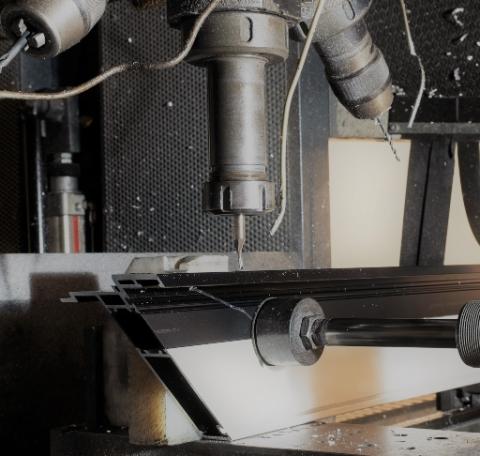

Aluminium

The aluminium used in our frames is manufactured in the UK to the highest standards and offers outstanding thermal insulation and security.

Silicone

We use the best quality silicone sealants from Dow Corning, tested for adhesion with coated surfaces and stainless steel finishes.

Hardware

The hardware and fixings used in the construction of our roof lights are specified to a minimum stainless steel grade A2.